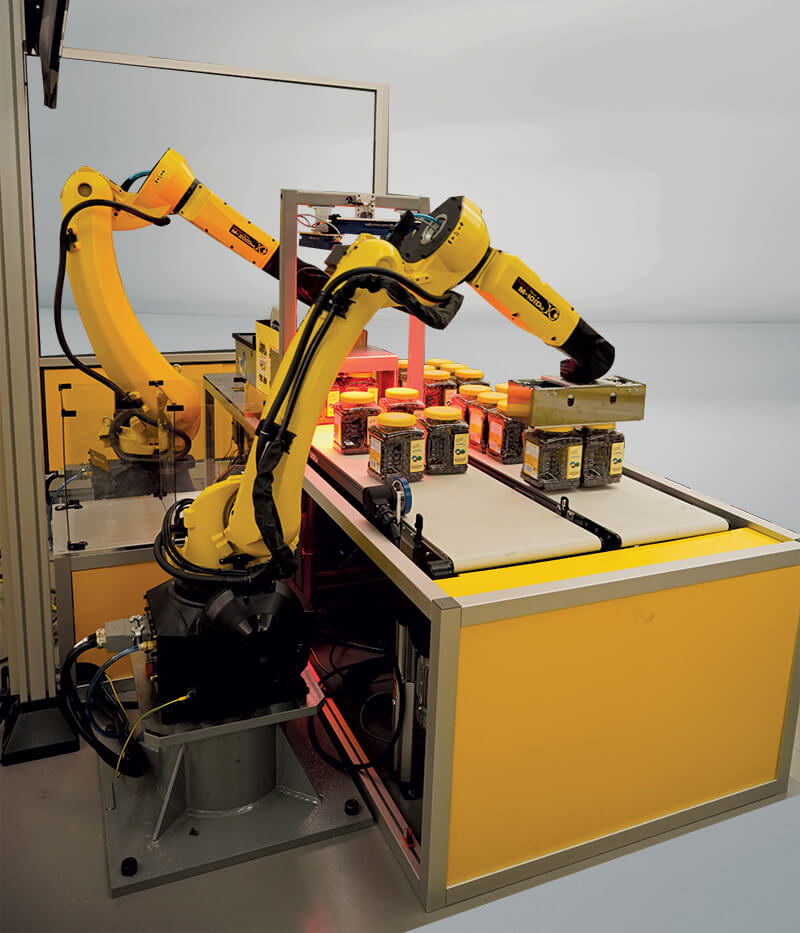

Robotic Material Handling

A robotic material handling application involves the use of robots to handle materials within a manufacturing or warehouse environment. This can include tasks such as loading and unloading materials, transporting goods, and organizing and storing products.

- Blister Packaging

Our Blister Packaging systems are built for top-notch performance and ease of use. Perfect for both pharmaceuticals and consumer products, these systems securely package your items and help keep your production moving quickly and smoothly with minimal waste.

- Bottling

Upgrade your bottling process with our robotic systems. They're designed to work with many different bottle sizes and types, filling and capping with great precision and speed. Our technology boosts your output and keeps things running smoothly from start to finish.

- Labeling

Improve your product's look with our fast robotic labeling systems. They can work with all kinds of label shapes and sizes, applying them neatly and accurately to make sure your products catch the eye on store shelves. Our systems are adaptable and reliable, streamlining your labeling needs.

Safer Handling

The benefits and advantages of using a robotic material handling application include:

- Increased Efficiency: Robots can handle materials faster and with more consistency than manual labor, reducing downtime and increasing overall productivity.

- Improved Safety: By automating the handling of heavy or repetitive tasks, robotic material handling applications reduce the risk of injury to workers.

- Increased Accuracy: Robots are equipped with sensors and vision systems that enable them to accurately perform material handling operations, reducing the risk of error or waste.

- Increased Flexibility: Robotic material handling systems can be easily reconfigured to handle different product sizes and shapes, making them a flexible solution for a wide range of industries.

- Improved Inventory Management: By automating the process of handling and organizing materials, robotic material handling applications can improve inventory management and ensure that products are stored efficiently and accurately.

- Customed Designed Solutions: South Coast Robotics can design an automated solution for your processes using a combination of robotics and custom tooling. We take into account the cost saving, repeatability, and robustness of the process to find the best solution.

Overall

Robotic material handling applications offer a cost-effective and flexible solution for improving the efficiency and safety of material handling operations. By automating the process of handling materials, companies can reduce downtime, improve accuracy, and increase overall efficiency.

INVEST IN YOUR FUTURE WITH AUTOMATION

Don’t get left behind, get ahead of the competition by automating your manufacturing processes. South Coast Robotics will work with you to provide the best automation system for your requirements We will spec in, implement and train you and your team on the software, hardware and controls systems that are included in your system. Your system will be ready to “plug and play” when delivered.

- Postal address

8065 E. Crystal Dr.

Anaheim, Ca. 92807

- Phone number

- +1 (888) 505-9332

- sales@southcoastrobotics.com